Project Development

Project Development 18 Febuary 2022

1. Our team Chemical Device

· Team Chemical Device: Automated

CO Monitoring & Ventilation System

· Background:

Around 2.6

billion people still cook using solid fuels (such as wood, crop wastes,

charcoal, coal and dung) and kerosene in open fires and inefficient stoves.

Most of these people are poor and live in low- and middle-income countries.

These cooking practices are inefficient and use fuels and technologies that

produce high levels of household air pollution with a range of health-damaging

pollutants, including small soot particles that penetrate deep into the lungs.

In poorly ventilated dwellings, indoor smoke can be 100 times higher than

acceptable levels for fine particles. Household air pollution (HAP), which

results from incomplete combustion of the solid fuels. à

Incomplete Combustion chemical equation: Fuel + O2 -> CO + Stack gases. 7.5

million people die from HAP annually most of them originating from lower income

countries.

Figure 1: Statistics on Deaths due to

Household Air Pollution

· What is currently being

done to help:

For example: United Nations and World Health Organization

(WHO)

· Advocacy and

Educational Efforts

Working to integrate guidance and resources for

supporting clean household energy into global health initiatives and

decision-support tools, such as the Global Action Plan for Pneumonia and

Diarrheal Disease (GAPPD).

Advocacy can help increase awareness of the

importance of providing and scaling up of cleaner household energy as a core

preventive public health measure.

· Providing Technical

Support to health-promoting household fuels and technologies

· Challenge despite

efforts:

1) Takes

a long time for solution to be developed and implemented in the process as such

organizations are working towards large-scaled, long-term solutions. But in the

meanwhile, it means more deaths every day.

2) Changing

rural people’s attitude and effectiveness of solution:

Programs to introduce clean cookstoves cannot simply

assume that these so-called improved stoves will be accepted by the rural household

or that they will benefit health. The open fires these rural people use to cook

has deep rooted connections to their cultures and hence carries the risk that

implementation of greener cooking methods will not improve health since the

rural people might not be open to change.

3) Affordability

Even if these organizations do implement greener

alternatives, the daunting task ahead is to ensure it is affordable and

scalable to hundreds of millions of households who already face financial

worries.

Resources:

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3672215/

https://borgenproject.org/cooking-fuel-in-developing-countries/

è Hence, this explains why our role is so

important.

·

THE ISSUE WE WANT TO SOLVE:

Solid

fuel use is closely linked to poverty and clean cooking technologies must be

affordable and desirable to families with limited and insecure incomes.

·

PROBLEM STATEMENT:

What

sustainable and/or affordable solution can we provide to prevent health

consequences arising from ineffective cooking methods i.e. household air

pollution to lower-income rural families whilst allowing them to hold onto

their beliefs?

· How our prototype

solves the Issue?

- Provides

a short term, affordable solution (refer to our

design specification table, total cost of prototype < $150, cheaper compared

to initiatives governments/organizations roll out which costs millions of

dollars and also take long to implement)

- Complete

autonomy of use for people (rural people won’t feel

restricted that they have to follow rules when using our prototype, unlike when

policies are implemented.)

- Sense

of independence and freedom for users

- A

catalyst to drive change

(rural

people might still want to use fuel to cook because of ties it has to their culture

so we can’t expect their behavior to change overnight hence the CO monitoring

and ventilation system i.e. our prototype, complements their current behaviors

and acts as a catalyst for change to cleaner sources of fuel à when they see how many times the ventilation had been triggered, we

hope they become more aware of how unsafe their current cooking method is and

be open to change)

·

EFFECTIVE

(It can effectively detect unsafe levels of CO, reflect

it on the LCD screen for the user to see and also provides a solution i.e.,

ventilation to return back environment to safety for user.)

·

HAND SKETCH OF FINAL CHEMICAL DEVICE:

Figure 2: Final Sketch

of Chemical Device

2. Team Planning, allocation, and execution

Team Members:

Serena – Chief Executive Officer (CEO)/Leader

Kenny – Chief Financial Officer

Kai Rong – Chief Operating Officer

Jerome – Chief Safety Officer

Finalized

BOM table:

Finalized Gantt Chart:

Planned:

Actual:

Changes are only in the Manufacturing of

prototype and Final Check Stages (highlighted in yellow 4.5 – 5.4)

Task Allocation:

· Serena and Jerome are

in charge of CAD fusion while Kai Rong and Kenny are in charge of the Arduino

Programming

· The team then comes together to 3D print, laser cut then assemble and prototype testing

3.

Design and Build

Process

In this section,

provide documentation of the design and build process.

Design

Process:

· Evolution of Idea to

Final Prototype (Using Hand Sketches & CAD Screenshots)

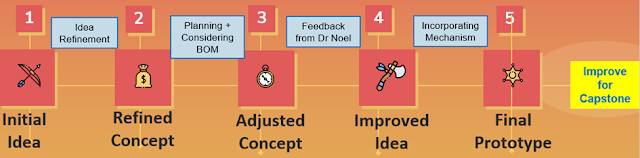

OUR JOURNEY

Figure 3: Our Journey

1.

Our Initial Idea

(Brainstorming & Ideation)

In the Figure below, the long rectangular box

was supposed to be a casing for the electronics i.e. Arduino Board, Breadboard

wiring, sensor (for monitoring of CO), LCD display etc, whereby we would

hotwire and connect a portable fan we would buy from external sources e.g.

Lazada to this electronic casing for the ventilation aspect of the prototype.

Figure 4: Initial Idea

Sketch

However, after going through the idea refinement

processes such as TRIZ, we realized we had to refine our initial idea as it was

not effective.

2.

Our Refined Idea (Idea

Refinement Processes)

In Figure 4, our initial idea, we realized that

our chemical device was placed in the surroundings itself this was ineffective

because it means that even after the fan blows the excess CO in order to

restore the CO level to be safe, this blown CO would not be redirected

elsewhere because it would just be blown back into the same surrounding air

i.e. we had not reduced the level of CO in the surroundings after all.

Hence, after going through TRIZ, we came to

realize that to refine our idea further, we had to change the local quality of

the air. (See Figure 5: Conclusions from TRIZ).

Hence, in order to change the local quality of

the air, we knew it meant the excess CO had to be directed out of the

surroundings. Hence we decided that our chemical produce had to be placed in

an enclosed space like a vent whereby it should have an inlet and outlet

opening for the air to enter and exit. This is so that when CO detected by the

sensor exceeds the limit the fan blows out the excess CO and as the outlet hole

is the only exit route, it would be directed out and escape externally , helping to change the

local air quality in the box to be of safe levels of CO.

Figure 5: Conclusions

from TRIZ

Figure 6: Refined Idea Sketch

(After Idea Refinement Processes)

3.

Adjusted Concept

(Planning Phase + Consideration of BOM)

As we

entered the Planning phase whereby we discussed who would take charge of which

components of the device and eventually build that as well as planning for our

budget in our Bill of Materials (BOM), we realized that a way to further reduce

the cost in our BOM was to not buy a portable fan from Lazada but instead

make use of the resources and skills we had i.e. Arduino Program a DC motor

with an attached fan propeller to rotate as a replacement to the fan. This

saved us approximately $30 and also the fact that we didn’t have to lag behind

our progress later on due to waiting on delivery time also made us a high

performing team. Another adjustment we made was the design for the electronics

housing case. Initially the design in the earlier 2 sketches showed the

electronics housing unit to be long but short in terms of height because we

thought we could bend the wires and save material. However after measuring the dimensions as we

prepared to enter the building stage, we realized we couldn’t bend the wires

and hence we had to build a smaller box inside of the larger box (vent) to act

as the electronics housing.

Figure 7: Adjusted Idea

Sketch

4) Improved Concept (After feedback

from Dr Noel)

At

this point, we were confident of our Adjusted Concept and hence had already

dived into the Computer Aided Design (via Fusion) part. However, when we had a

Microsoft Teams consultation with Dr Noel, he gave us some feedback (in the paraphrased

quotes) which prompted us to change our entire design i.e.

· “Think about the fact

that your device is going to be used as a kitchen fumehood. How should the

airflow be in that case?”

· “Would the current orientation provide

sufficient negative suction for the airflow in and out?”

· “If you place your DC

motor this way i.e. simply rested on a stand, wouldn’t it vibrate and wouldn’t

that affect the performance of ventilation?”

· “I currently cant

visualize it to be a fumehood, how will you change your design to replicate one?

Look at the resources in DCHE blog”

Hence,

we improved our design by firstly changing the orientation to be vertical

I.e. the airflow inlet and outlet would be vertical now instead of horizontal

earlier. This was because in order for our prototype to solve the issue we

wanted to, it would be used as an affordable kitchen fumehood hence, the air

from the cooking would rise and travel upwards vertically. This also meant that

the fan which provides ventilation to blow out excess CO would now be placed

vertically facing upwards. This was to ensure we could create negative

suction pressure for the air to be drawn in and later CO exit out. Hence to

provide sufficient inlet air flow as well as for the general appeal to look

like a kitchen fumehood, we created a bottom hood like structure. To hold in

place the fan connected to the DC motor to ensure the ventilation provided is

efficient, we also decided to make a DC motor casing which would also act as

a stand to allow the fan to prop out of the electronic casing as well. The

air would enter from the ghood vertically upwards and exit through the top hole

of the cylindrical pipe. There is a gap between the inner and outer boxes as

the inner box is completely sealed with just a hole for the fan to be protruding

out of it but still in the outer box.

Figure 8: Improved Idea Sketch

5) Final Prototype (with Mechanism)

We

then decided to add a Lever Mechanism which would be operated using a servo

motor. The purpose of this is to make the air flow exiting the device to be

automated. For our earlier Improved Product, the plan was for the cylindrical

pipe to always be opened however we realized this meant that there could be

clean air lost. And for already poorly ventilated spaces where our target

audience lives this could be more harm than good. Hence to prevent this it

meant that our air outlet pathway should only be open when it needs to i.e.

when CO levels are unsafe. Hence to make this automated, there will be a cap on

the cylindrical pipe which would be connected by a lever. When CO levels are

unsafe and the fan turns on, the servo would also turn on to push the lever and

open the cap as the servo turns 180 degrees angle.

Figure 9: Final Chemical Device

(With Mechanism)

Building

Process:

Measuring of dimensions to double check and make changes in our parametrically design fusion files before laser cutting or 3D printing straight away.

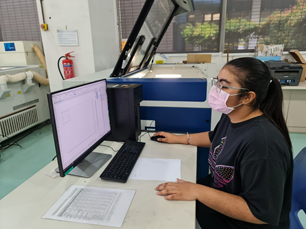

Jerome and Serena designing the parts in Fusion 360

The team then came together and went to fablab to laser cut our parts which includes the inner box and the outer box

Hero shot of laser cut parts

Sanding of laser cut sides – to ensure sides are smooth such that they will have better adhesive when gluing them together

Cardboard prototying where the main skill used was scoring to form the cylinder shape tube as well as to make a box shape for the servo to sit in

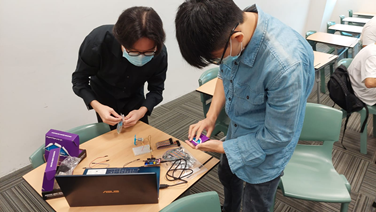

Kai Rong and Kenny programming the Arduino for our product and was successful to do so including for the servo

Hero Shot of Arduino Programming

Code for our product which uses the IF Else function to program such that when CO level is more than 9pmm, the message will display saying CO-unsafe Fan On and the fan would also be switched on

|

#include <MQ2.h> #include <Wire.h> #include <LiquidCrystal_I2C.h> LiquidCrystal_I2C lcd(0x27, 16, 2); //

CHANGE 0X3F TO 0X27 AS LCD ADDRESS int Analog_Input = A0; int co; int dc_motor = 13 ; MQ2 mq2(Analog_Input);

void setup() {

Serial.begin(9600);

lcd.begin();

lcd.backlight();

mq2.begin();

pinMode(Analog_Input, INPUT);

pinMode(13, OUTPUT); } void loop() {

float* values = mq2.read(true); //set it false if you don't want to

print the values in the Serial

//co = values[1]; co

= mq2.readCO();

lcd.setCursor(0, 0);

lcd.print(" CO:");

lcd.print(co);

lcd.print(" PPM");

if(co >= 9) {

digitalWrite(13,HIGH);

lcd.setCursor(0,1);

lcd.print("CO-Unsafe Fan on"); // Print a message to the

LCD. }

else

{

digitalWrite(13, LOW);

lcd.setCursor(0,1);

lcd.print("CO-Safe Fan off"); // Print a message to the LCD. } } |

The team came

together to 3D print parts like L-brace to support the inner box and the

Dc-motor case

Hero Shot of 3D printed parts

The team then assembled our product using acrylic glue from W319 (chloroform)

Hero shot of final product

Allocated

work:

Part 1. Design and Build of Outer Box (done by Serena). Link it to Serena’s blog:https://cp5070-2021-2b04-group2-serena.blogspot.com/p/project-development.html

Documentation for

task 1.

Part 2. Design and Build of DC Motor Casing (done by Serena). Link it to Serena’s blog:https://cp5070-2021-2b04-group2-serena.blogspot.com/p/project-development.html

Documentation for

task 2.

Part 3. Design

and Build of Inner Box (done by Jerome).

Link it to Jerome’s

blog: https://cp5070-2021-2b04-group2-jerome.blogspot.com/p/project-development.html

Documentation for task 3.

Part 4. Design

and Build of L brace (done by Jerome).

Link it to Jerome’s

blog: https://cp5070-2021-2b04-group2-jerome.blogspot.com/p/project-development.html

Documentation for task 4.

Part 5. Programming of DC motor, Sensor

and lcd (done by Kai Rong & Kenny). Link it to Kai Rong & Kenny’s blog

Kenny: https://cp5070-2021-2b04-group2-kenny.blogspot.com/p/project-development.html

Kai Rong: https://cp5070-2021-2b04--group2-kairong.blogspot.com/p/project-development.html

Since we learnt about the use of Tinkercad Simulation, I decided to try out programming of the product in Tinkercad as compared to just heading blinding into programming it.

I was able to program the CO system in Tinkercad, when there is CO, the DC-motor would start spinning.

So me and kenny tried to connect and program the lcd, Co sensor following the Tinkercad Simulation, however, it did not work as the LCD display does not light up.

Then we went online and found a helpful video that showed how to connect a LCD display and MQ2 CO sensor to arduino. The video also showed us a sample code of measuring CO, LPG and Smoke in the air then displaying it on the LCD display. From the video we were also able to get the library for MQ2. https://www.youtube.com/watch?v=MMUsPS5HUYA

Following the video, we were able to connect the LCD display and the CO sensor as in the serial monitor we were able to see the readings of CO. From the sample code, I removed the codes for LPG and smoke since they are not needed in our CO- product. By testing the code, I was able to realised that to display a message on the lCD display, I could use the function lcd.print(message) to print the message I want it to say as well as lcd.setCursor(0,0) to set the position of where the message will be printed out on the LCD.

Since we were programming it in school and was not allowed to burn in school, we tried testing by letting the fan to be switched on when CO level was low (<9ppm). But after connect the dc-motor, the dc-motor did not spin. After some thinking, we realised our mistake as we had forgotten that we needed a transistor and resistor. Thankfully we documented programming a dc-motor under the Arduino Programming task, so we were able to follow how to connect the dc-motor. Then the dc-motor was spinning.

For the coding, I tried using the IF..Else function from programmable button such that if CO is high (>9ppm) it would perform a function or else perform another function. In the first code, the problem encountered was that when the fan switches on, the LCD display would then switched off. The issue was that the code that measures the CO and displays it on the LCD highlighted in yellow was in the void setup, so when the action occurs in the void loop, the LCD does not display.

|

#include

<Wire.h> #include

<LiquidCrystal_I2C.h> LiquidCrystal_I2C

lcd(0x27, 16, 2); // CHANGE 0X3F TO 0X27 AS LCD ADDRESS int

Analog_Input = A0; int co; int dc_motor

= 13 ; MQ2

mq2(Analog_Input); void setup()

{ Serial.begin(9600); lcd.begin(); lcd.backlight(); mq2.begin(); pinMode(Analog_Input, INPUT); pinMode(13, OUTPUT); float* values =

mq2.read(true); //set it false if you don't want to print the values in the

Serial //co = values[1]; co = mq2.readCO(); lcd.setCursor(0, 0); lcd.print(" CO:"); lcd.print(co); lcd.print(" PPM"); } void loop() { if(Analog_Input >= 9) { digitalWrite(13,HIGH); lcd.setCursor(0,1); lcd.print("CO-Unsafe Fan on");

// Print a message to the LCD. } else { digitalWrite(13, LOW); lcd.setCursor(0,1); lcd.print("CO-Safe Fan off"); //

Print a message to the LCD. } } |

Then for my second code, I tried to separate the fan switching on/off and LCD display message into 2 If..else function (highlighted in green). But this caused the dc-motor to switch on and off every few seconds switching with displaying the LCD message. The problem is that it had to be under 1 if else function if not there will be two seperate commands interchanging at an interval.

|

#include

<Wire.h> #include

<LiquidCrystal_I2C.h> LiquidCrystal_I2C

lcd(0x27, 16, 2); // CHANGE 0X3F TO 0X27 AS LCD ADDRESS int

Analog_Input = A0; int co; int dc_motor

= 13 ; MQ2

mq2(Analog_Input); void setup()

{ Serial.begin(9600); lcd.begin(); lcd.backlight(); mq2.begin(); pinMode(Analog_Input, INPUT); pinMode(13, OUTPUT); float* values

= mq2.read(true); //set it false if you don't want to print the values in the

Serial //co = values[1]; co = mq2.readCO(); lcd.setCursor(0, 0); lcd.print(" CO:"); lcd.print(co); lcd.print(" PPM"); } void loop() { if(Analog_Input >= 9)

{ digitalWrite(13,HIGH);

}

else

{

digitalWrite(13, LOW);

if(Analog_Input >= 9)

lcd.setCursor(0,1);

lcd.print("CO-Unsafe Fan on"); // Print a message to the

LCD.

}

else

{

lcd.setCursor(0,1);

lcd.print("CO-Safe Fan off"); // Print a message to the LCD. } } |

Then I redid the code again, this time I placed the measurement of CO and display message (highlighted in yellow) in the void loop such that it would be performed together with the If...else function keeping the If..else from the first code (highlighted in green). I also changed the input from analog_input to co (highlighted in cyan) to ensure that my input was the co measurement as I thought that the input might be a problem. To my delight, we code was successful in working including when testing with actual burning of CO.

|

#include

<MQ2.h> #include

<Wire.h> #include

<LiquidCrystal_I2C.h> LiquidCrystal_I2C

lcd(0x27, 16, 2); // CHANGE 0X3F TO 0X27 AS LCD ADDRESS int

Analog_Input = A0; int co; int dc_motor

= 13 ; MQ2

mq2(Analog_Input); void setup()

{ Serial.begin(9600); lcd.begin(); lcd.backlight(); mq2.begin(); pinMode(Analog_Input, INPUT); pinMode(13, OUTPUT); } void loop() { float* values = mq2.read(true); //set it false if you don't want to

print the values in the Serial //co = values[1]; co = mq2.readCO(); lcd.setCursor(0, 0); lcd.print(" CO:"); lcd.print(co); lcd.print(" PPM"); if(co >= 9) { digitalWrite(13,HIGH);

lcd.setCursor(0,1);

lcd.print("CO-Unsafe Fan on"); // Print a message to the

LCD.

}

else

{

digitalWrite(13, LOW);

lcd.setCursor(0,1);

lcd.print("CO-Safe Fan off"); // Print a message to the LCD. } } |

Part 6. Programming of Servo Motor &

Build of Mechanism (done by Kai Rong). Link it to Kai Rong’s blog:https://cp5070-2021-2b04--group2-kairong.blogspot.com/p/project-development.html

For our mechanism, we decided to implement a lever that would be perform by a servo that opens the lid of our fume hood to allow air to exit after being sucked in from the bottom via the negative suction of the fan. We decided to have a lid covering the top cylinder outlet that is connected to a servo which is supported by a stand.

Since this mechanism implementation was last minute, we had to make it out of cardboard and use a seperate arduino as we had already assembled our product and had no way of assessing the inner electronic box (which is one improvement that could be done in the next version to make the box a hinge box that allows one of the side to be open).

I firstly measured on the dimension of the servo and the height of the servo I want it to sit the the case. Then I scored a blank cardboard such that it can be folded into a box shaped and cut out the base dimension of the servo as the table for the servo to sit in. Then i cut out a hole at the back to allow the wire for the servo to come out.

For the code, I remember that we programmed a servo during the arduino pre practical individual activity as well as during the arduino practical where we had to program a unicorn to flap. So I went back to the blog to check on the documentation to refresh on programming a servo. In this case since I had to use a seperate arduino, I decided to use the programmable button to make the servo move such that I would be able to showcase it in the video, but in actual the servo would open the lid simulatenously as the dc-motor turns on when CO level is high.

Using the servo sweep example in arduino, and adding the programmable button code on serial.begin, pin input and output as my servo. Then using the if else function such that when the button is pressed, the servo would open to 180oand close when eitherwise.

|

#include

<Servo.h> Servo

myservo; // create servo object to

control a servo // twelve

servo objects can be created on most boards int pos =

0; // variable to store the servo

position void setup()

{ Serial.begin(9600); pinMode(2, INPUT_PULLUP); pinMode(9, OUTPUT); myservo.attach(9); // attaches the servo on pin 9 to the servo

object } void loop() { //read the pushbutton value into a variable int sensorVal = digitalRead(2); //print out the value of the pushbutton Serial.println(sensorVal); if (sensorVal == HIGH) { myservo.write(180); // tell servo to go to position

in variable 'pos' } else { myservo.write(0); // tell servo to go to position

in variable 'pos' delay(15); // waits 15 ms for the

servo to reach the position } } |

Part 7: Integration of all parts and electronics (done by Jerome) Link of Jerome’s Blog:https://cp5070-2021-2b04-group2-jerome.blogspot.com/p/project-development.html

Documentation for

integration.

Part 8: Assembling of FINAL Prototype (done by EVERYONE) Links of EVERYONE’s Blog

KaiRong:https://cp5070-2021-2b04--group2-kairong.blogspot.com/p/project-development.html

Jerome:https://cp5070-2021-2b04-group2-jerome.blogspot.com/p/project-development.html

Sernea:https://cp5070-2021-2b04-group2-serena.blogspot.com/p/project-development.html

Kenny:https://cp5070-2021-2b04-group2-kenny.blogspot.com/p/project-development.html

The team went to W319 to assemble our product using the acrylic glue (chloroform) where we taught how to properly handle and use the glue by Dr Noel. We had to switch on the fume hood when using the acrylic glue then we had to use a needle syringe to inject the glue where when injecting the glue, the glue can be seen flowing throught the gaps when shined with a flash light. Before gluing, we need to assemble the product with tapes to shape it in the way we want. After assembling the product, with Ms Serene's permission, we were allowed to leave our product over the weekend before collecting in on Monday to allow the glue to strengthen as we were afraid that the product might fall apart on the way back home.

Part 9: Prototype Testing, taking of video (done by Kai Rong) Link to Kai Rong’s blog:https://cp5070-2021-2b04--group2-kairong.blogspot.com/p/project-development.html

After assembling the product, we had to test our prototype perform neccessary troubleshooting and take a video to demostrate our product for the presentation since our product is not able to perform live demostration due to it having the need to burn which is not allowed in school. So the video taking had to be done at home.

When testing the prototype with mechanism before taking the video, I encountered a major hiccup that the dc-motor fan does not turn on even though it turned on for a while when I uploaded the code. I guessed that the either the dc-motor has a problem or a wire attaching the dc motor has issues. So I had to make a decision to de-assemble the product since we wanted to have a successful working product for videoing. I had to break off one of the L-brace in order for the inner box to come out (which is one improvement for future prototype that can make the outer box a hinge box that one of the sides can be open to easily assess the inner box) as I did not want to break the outer box. In order to assemble back the inner box, I had to temporarily use a cardboard to fill back that empty gap.

Part 10: Presentation

Link to presentation file

Link

to vid of product

https://drive.google.com/file/d/14_posj2nX8yFT_2yQBLpnF8LjScURh5G/view?usp=sharing

4. Problems and solutions

Problems on Programming

-

Programming in Tinkercad Simulation works but was not

able to be implemented (LCD display does not light up)

-

Solution: Found a video that showcase how to connect CO

sensor and LCD display to Arduino

-

Coding: When the fan is switched on, LCD display turns

off (LCD should be on at all time to show CO reading); When CO level is high >9ppm,

fan switches on and off every few seconds (Fan should be on continuously when

reading of CO is high)

-

Solution: Used a mix of programmable button (IF…ELSE

function) and servo (poswrite180o) codes.

Problems on Prototype 1 (based on Sketch 4)

|

Problems |

Solution |

|

- Dimension of the

laser cut parts Ø Did not take into

consideration of excess length for power supply cable in the box Ø Assembling of walls

were uneven Ø LCD display and CO

sensor screw holes were not aligned

|

• Proper

planning and measurement of all parts taking into consideration of necessary

excess length • Power

supply need not be in the box – Cut a hole through the walls for the wire to

pass through

|

|

- Assembling of

product were not done well Ø Used of wrong glue (Hard

Plastic Glue) and did not know how to properly apply them Ø Lack of way to

support the inner box in the outer box Ø Base of the outer box

to shape like the fume hood were not able to be chamfer by the laser cutter Ø DC-motor wire were

too short

|

• Use

acrylic glue from W318 (chloroform) to assemble the product • Cardboard

prototype the base of the outer box (another problem not strong enough to

support the weight of the box – 3D print) • 3D print

L-brace to support the inner box to the outer box • Soldering

of DC-motor wires

|

Problem of Prototype 2 (based

on Sketch 5)

|

Problem |

Solution |

|

DC-motor case (hinge

box) does not close fully. However, it serves the purpose of holding the dc-motor,

so it is unnecessary to reprint |

Increase

hinge gap |

|

L-brace used to

support the inner box to the outer box is too short |

Increase length in parametric

design L-brace and reprint |

|

DC-motor does not

turn when taking video (DC-motor side wires came out) |

De-assemble product

to remove DC-motor (had to break one of the L-brace-then fit cardboard to

fill back the empty gap) and change to another DC-motor |

5. Project Design Files as downloadable files

Arduino:

CO system code:https://drive.google.com/file/d/1cXgpK-Qe2hwZ73Zxi-eVw1etVy9GImwJ/view?usp=sharing

Servo Code:https://drive.google.com/file/d/16KfV-mVFujIM680jdprBxRwNdpd7eDDX/view? usp=sharing

MQ2 library:https://drive.google.com/drive/folders/1nWQTAlFILeUSal-LZAw4vsjPTBo3FxOS?usp=sharing

Outerbox:

Outerbox fusion:https://drive.google.com/file/d/17riFTkPHhfT9ir7lr11oGAv0wVEisQ4o/view?usp=sharing

Outerbox dxf:https://drive.google.com/file/d/1TC6N9ifS0JZWnVs0wHUZuB8MPprZaLTM/view?usp=sharing

Innerbox:

Inner box:https://drive.google.com/file/d/16US4Ee6Yv6QzoO5Eqw8VK0YuUZaBvMfb/view?usp=sharing

LCD fusion:https://drive.google.com/file/d/1dVnbvC02QMagQYt3TKABhVewsc-Rj1vu/view?usp=sharing

LCD dxf:https://drive.google.com/file/d/1rxrNicnFk8TmBCd0i6dgwn8vhhc5QSP_/view?usp=sharing

Top side and Blank side fusion:https://drive.google.com/file/d/1lM3QLU2YQ8SOM61EEU-sjctBiXybhDj5/view?usp=sharing

Top side and Blank side dxf :https://drive.google.com/file/d/1VcCbOx9nch3ucIoMhNGhccHpeng7kutX/view?usp=sharing

Sensor side fusion: https://drive.google.com/file/d/1VcCbOx9nch3ucIoMhNGhccHpeng7kutX/view?usp=sharing

Sensor side dxf:https://drive.google.com/file/d/1VcCbOx9nch3ucIoMhNGhccHpeng7kutX/view?usp=sharing

DC-motor casing:

DC-motor case fusion:https://drive.google.com/file/d/121mqtkS4R6dp3yc4JbDk6e5Io0595tq0/view?usp=sharing

DC-motor case stl:https://drive.google.com/file/d/1BOH6P994_IGjI2LtmbPETqKZ--EcYEMr/view?usp=sharing

DC-motor case cura slicer :https://drive.google.com/file/d/1g_9KzJFfzKkLQkiqxXrK9FlGLSbBFkgX/view?usp=sharing

L-brace:

L-brace fusion: https://drive.google.com/file/d/1MDV__H6hzEsr-vI1s9w-zVgIgiBYcPlr/view?usp=sharing

L-brace stl:https://drive.google.com/file/d/1bpRbnSHUBbb82xOFN4qs1P7jzukDxXdA/view?usp=sharing

Final Integrated Product:https://drive.google.com/file/d/1AKAxa2QOVvrd1-gg57HTZwAgEcealHM_/view?usp=sharing

Reflection

Although the team experienced many hiccups, but overall it was a fun and fruitful experience as we were able to apply all the skills learn (CAD, laser cutting, 3D printing and arduino programming) all at once learning how to integrate all the different skills learn in this module. In addition it was a great sense of happiness when we saw that our hard work and effort was rewarded when our product was successful. Throughout this project development, I learned the importance of documentation that I thought was not any need in the past. But for example when programming the code for our product, having the blog where we had documented pass activity had been a great help with the whole process as without it, it would be like starting from the begining since we had forgotten about what we had learn. I would also like to show appreciation to all the TEs and lecturers that provided us assistance along the way as without them, we would not have been able to get to this end point.

Comments

Post a Comment